Why in the News?

The Ministry of New and Renewable Energy (MNRE) has released Scheme Guidelines for funding of testing facilities, infrastructure, and institutional support for development of Standards and Regulatory framework under the National Green Hydrogen Mission.

Key-features of the Guidelines

- Budgetary Outlay: Rs. 200 Crore till FY 2025-26.

- Objective: To identify the gaps in the existing testing facilities for components, technologies and processes in the value chain of Green Hydrogen & its derivatives.

- National Institute of Solar Energy (NISE) will be the Scheme Implementation agency (SIA).

Implementation Methodology:

- SIA will identify the test facilities.

- SIA will issue call for proposals (CfP) in consultation with MNRE for establishment of testing facilities.

- The proposals will be evaluated by a Project Appraisal Committee (PAC).

- Selected agencies will be recommended by PAC to MNRE to issuing sanctions.

- Letter of Award shall be issued to Executing Agency (EA) by SIA.

- Funding and Disbursement: MNRE will fund up to:

- 100% of the capital cost (for Government entities).

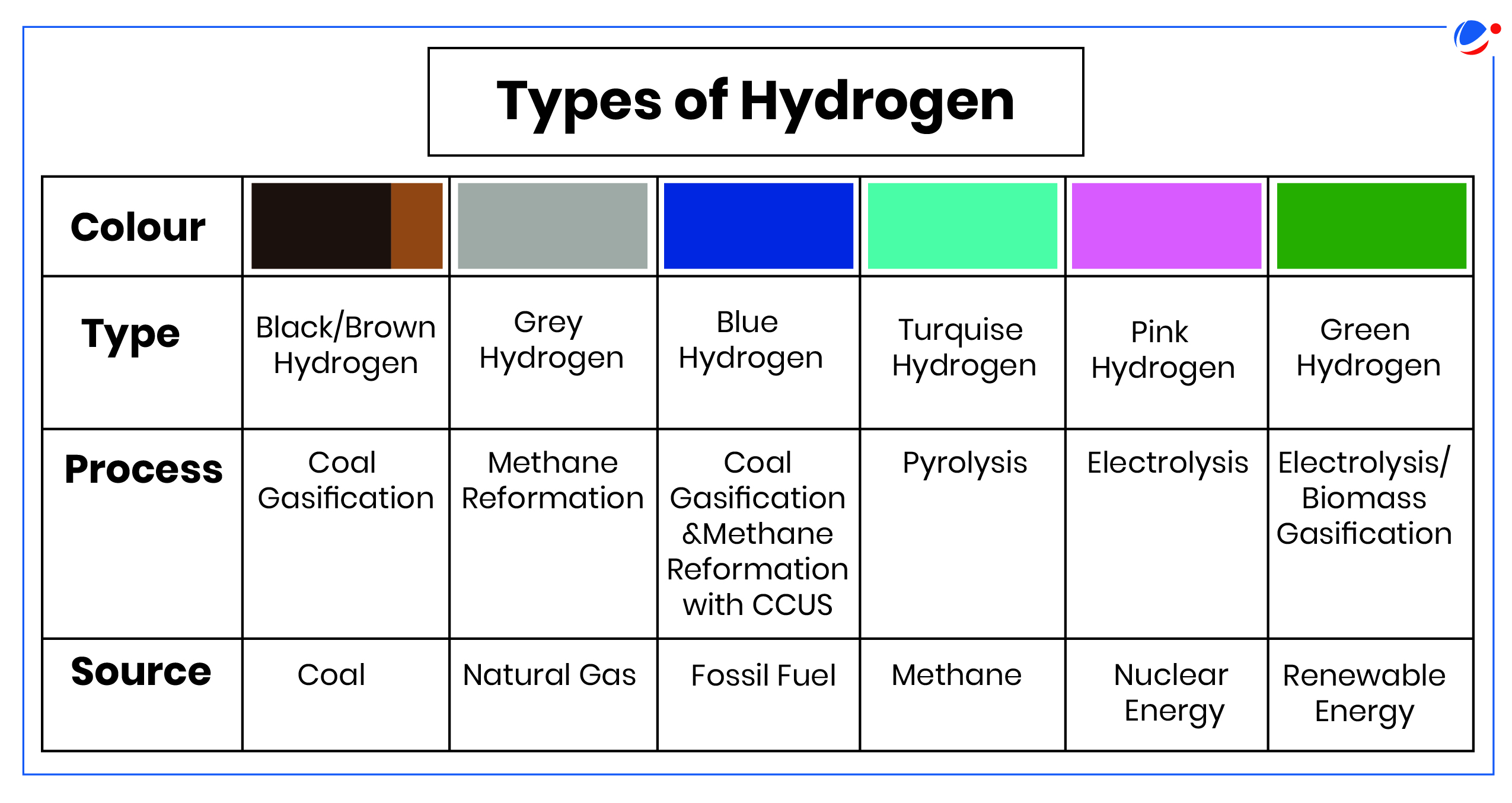

What is Green Hydrogen (GH2)?

- It refers to hydrogen produced through electrolysis, which splits water molecules (H2O) into hydrogen (H2) and oxygen (O2) using electricity generated from renewable sources like solar, wind, hydro etc.

- Another method of producing GH2 is from biomass, which involves the gasification of biomass to produce hydrogen.

- Applications of GH2: Fuel Cell Electric Vehicles (FCEVs) Aviation and Maritime, Industry (Fertilizer Refinery, Steel, Transport (Road, Rail), Shipping, Power Generation.

- 70% of the capital cost (For Non-Government entities)

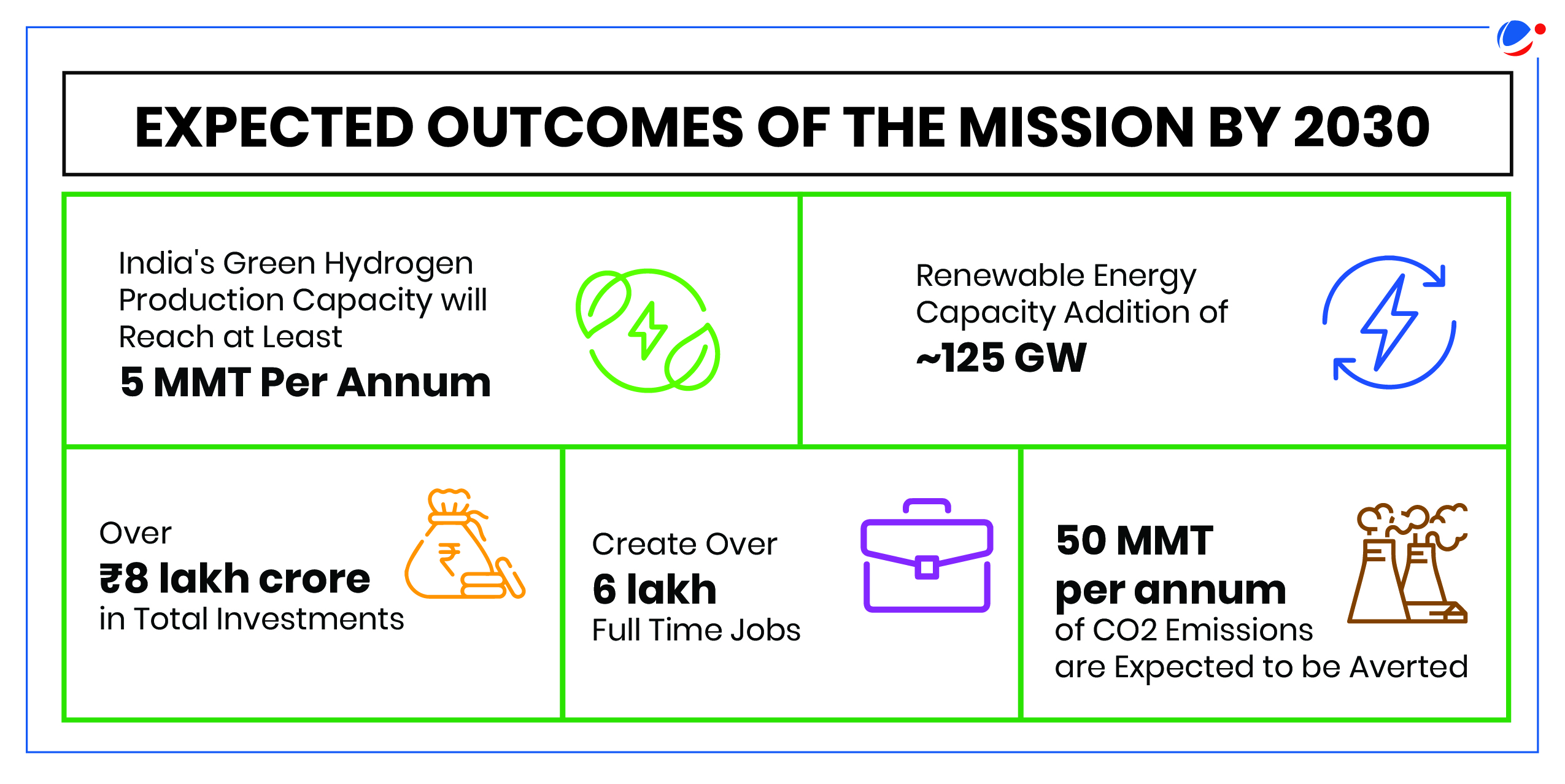

About National Green Hydrogen Mission (NGHM)

- Launched in 2023, with an outlay of ₹ 19,744 crore.

- Duration: Phase I (2022-23 to 2025-26) and Phase II (2026-27 to 2029-30).

- Objective: To make India a Global Hub for production, usage and export of Green Hydrogen and its derivatives.

Key components:

- Facilitating demand creation through exports and domestic utilization.

- Strategic Interventions for Green Hydrogen Transition (SIGHT) programme, which includes incentives for manufacturing of electrolysers and production of green hydrogen.

- Pilot Projects for steel, mobility, shipping, decentralized energy applications, hydrogen production from biomass, hydrogen storage, etc.

- Development of Green Hydrogen Hubs (for e.g., 3ports namely Deendayal (Kandla, Gujarat), Paradip (Odisha) and V.O. Chidambaranar (Tuticorin, Tamil Nadu) have been identified.

- Establishing a robust framework of regulations and standards.

- Research & Development programme.

Initial steps taken under NGHM

- GAIL Limited has started India's maiden project of blending Hydrogen in City Gas Distribution grid in Indore (Madhya Pradesh)

- NTPC Limited has initiated blending of Green Hydrogen up to 8% in PNG Network at NTPC Surat (Gujarat).

- Hydrogen based Fuel-Cell Electric Vehicle (FCEV) Buses in Greater Noida (Uttar Pradesh) and Leh by NTPC.

- Oil India Limited has developed a 60-kW capacity hydrogen fuel cell bus, which is a hybrid of an electric drive and a fuel cell.

Challenges in green hydrogen adoption

- Economically viability: The NITI Aayog report states that the current cost of producing green hydrogen via electrolysis, ranging from $4.10 to $7 per kg, is still too high to compete with grey or brown hydrogen.

- Difficulty in Hydrogen Storage: As hydrogen as a gas typically requires high-pressure tanks (350–700 bar) tank pressure and as a liquid requires cryogenic temperatures because the boiling point of hydrogen at one atmosphere pressure is −252.8°C.

- Lack of Skill: In the domain of hydrogen production, the workforce demand is expected to reach ~2.83 lakhs, encompassing roles in design and planning, installation, commissioning, and green hydrogen production units.

- Resource scarcity: Green hydrogen is produced by electrolyzing water, which can require up to 9 Liters of water per kilogram of hydrogen (As per International Energy Agency).

- Lack of global standards on carbon intensity & safety: Regulations for green hydrogen definitions, transportation, storage, safety, and usage vary widely across countries.

Way forward

- Reduce cost: India aims to reduce green hydrogen production costs to $1 per kg by 2030 through low-cost renewable energy, local electrolyser manufacturing, and technological advancements.

- Incentives: For new applications, where the viability of using green hydrogen is still at early stage, necessary incentives should be designed.

- For example, Production-Linked Incentive (PLI) scheme for green steel targeting export markets.

- Research and Development: India should invest $1 billion in R&D by 2030 to advance commercial green hydrogen technologies and promote alternative methods like bio-hydrogen

- Initiate green hydrogen standards and a labelling programme: A digital (AI/ML equipped) labelling and tracing mechanism certification of origin should be initiated.

- Public entities such as BIS (Bureau of Indian Standards) and PESO (The Petroleum and Explosives Safety Organization) are expected to take a leading role in this process.

- Construct an inter-ministerial governance structure: An interdisciplinary Project Management Unit (PMU) with globally trained experts must be created which can dedicate fulltime resources to effectively implement the mission.