Why in the News?

Ministry of Coal has launched a pioneering Underground Coal Gasification pilot project in Jharkhand's Jamtara District.

More about News

- In 2015, a dedicated policy framework for development of UCG in coal and lignite bearing areas in India was approved by Ministry of Coal.

- In alignment with this policy, Coal India selected the Kasta coal block of Jamtara District to implement UCG technology tailored to Indian geo-mining conditions.

Underground coal gasification (UCG)

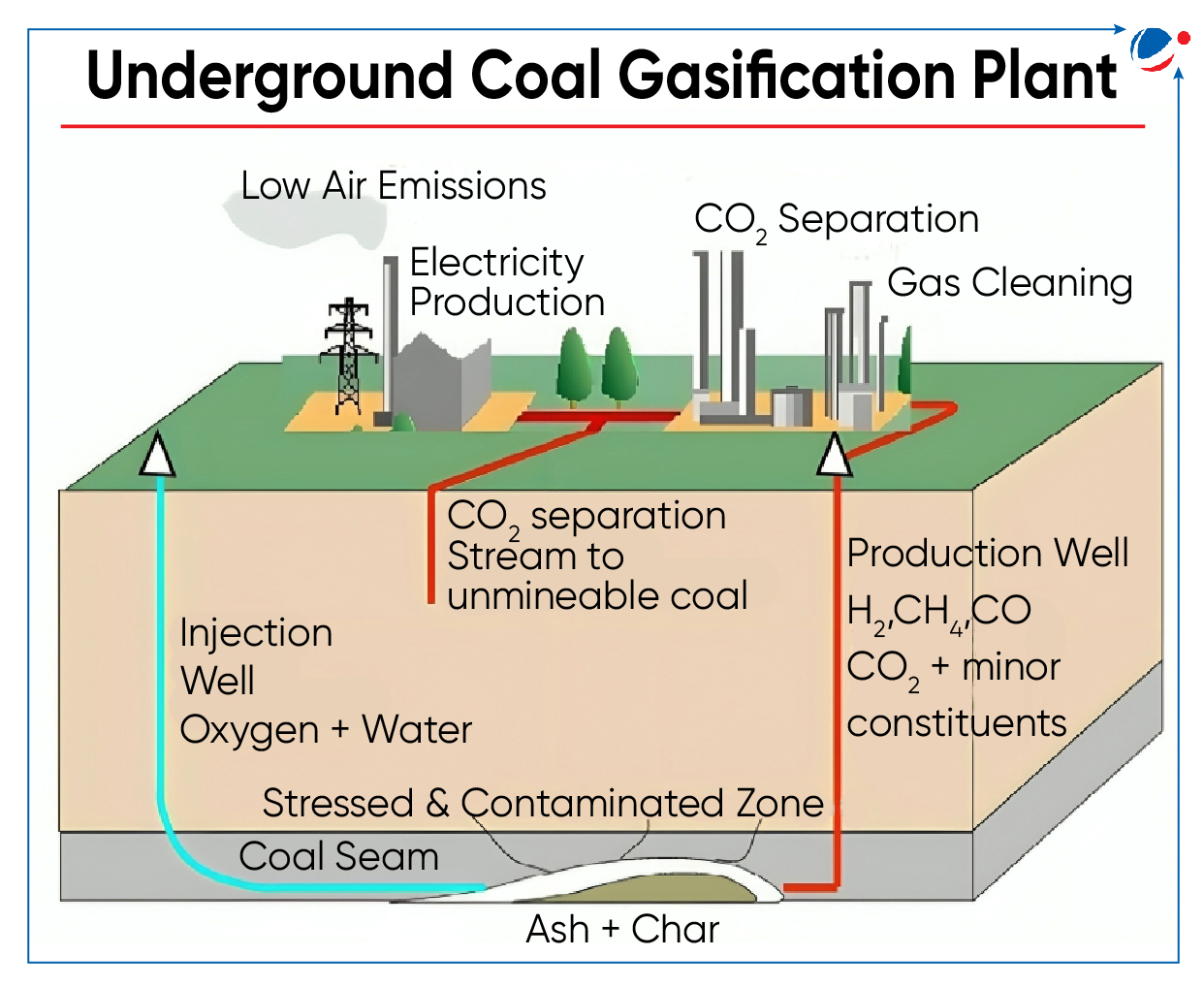

- UCG is an energy manufacturing process whereby coal is gasified or chemically converted into a synthesis gas (syngas) in its original coal seam.

- UCG gas is similar to surface coal gasification gas, typically a mixture of methane (CH4), carbon dioxide (CO2), hydrogen (H2) and carbon monoxide (CO).

- UCG is the in-situ combustion of the coal seam to produce usable gas.

- The process is initiated by injecting steam and air/oxygen into the seam and igniting it, requiring temperatures over 1000°C.

- The resulting products vary based on coal type, temperature, pressure, and whether air or oxygen is used for combustion.

Products of UCG

- Electricity: The hot syngas from UCG can be used to make steam to drive a steam turbine that generates electricity or it can be combusted to produce steam to drive an electric turbine.

- Chemical Feedstock: Syngas can be used as chemical feedstock (after its H2 to CO ratio is suitably balanced) to produce methanol, hydrogen, ammonia and other chemical products.

- Production of Hydrogen: Coal is the obvious source for hydrogen which is potentially an important near zero carbon energy carrier of the future.

- UCG as a hydrogen generator coupled with a solid oxide fuel cell (SOFC) to generate electrical power directly has been studied by Indian experts.

Benefits of UCG

- Access to unmineable coal: UCG opens up the prospect of accessing trillions of tonnes of otherwise unmineable coal.

- Reduced capital expenditure: In a UCG commercial development, several expensive process units and components that are needed in a coal mining and surface gasification complex are eliminated, including coal mining, transportation, storage etc.

- Energy Density: Compared to typical coal bed methane extraction, UCG needs less than 3% of the land area needed for CBM to produce the same amount of gas energy.

- Other benefits

- Reduce dependence on imports

- No environmental impacts traditionally associated with coal mining and handling

- UCG has unique potential in recovering heating value from high ash coal.

Government Initiatives for Coal Gasification

|

Concerns associated with UCG

- Induced Subsidence: The void created by UCG may cause significant deformation both in the remaining coal and surrounding rocks.

- Contamination of Groundwater: During UCG various chemicals form in the coal seam including phenols, benzene, carbon dioxide, etc. There's a risk these substances could migrate beyond the gasification area and potentially contaminate nearby groundwater sources.

- Lack of proven Technology: Lack of technology for conversion of India's coal to syngas.

- High technology cost affects Syngas & downstream products costs & Project viability.

- Unsteady-state process: UCG is inherently an unsteady process since a number of parameters, such as the growth of the cavity, inherent variation in the properties of the coal along the seam, quantity of water influx, ash layer build-up, affect the rates of the homogeneous and heterogeneous reactions occurring therein.

Conclusion

Underground Coal gasification offers vast potential to transform coal into valuable products. The government's schemes and incentives aim to attract public and private sector investments, fostering innovation and sustainable development of the coal sector in India.